Magnetic Nanoparticles

นอกจากการดูบทความนี้แล้ว คุณยังสามารถดูข้อมูลที่เป็นประโยชน์อื่นๆ อีกมากมายที่เราให้ไว้ที่นี่: ดูความรู้เพิ่มเติมที่นี่

Guide to magnetic beads / MagBeads for protein purification

NTA versus IDA: what’s the difference?:

https://cubebiotech.com/ntaversusidawhatsthedifference

NickelNTA MagBeads:

https://cubebiotech.com/products/magneticbeads/hisaffinitymagbeads/nintamagbeads/

Indigo MagBeads:

https://cubebiotech.com/products/magneticbeads/hisaffinitymagbeads/indigonimagbeads/

MagBead Separator:

https://cubebiotech.com/products/magneticbeads/magbeadseparator/

Wash Buffer and Elution Buffer:

https://cubebiotech.com/media/pdf/fa/ec/5d/HIS_Pur_Native_MagBead.pdf

MagBeads Purification Steps:

Step 1:

The usual starting point of a MagBead protein purification is a cell lysate in which the proteins of interest are mixed together with every other proteins the expression cells had produced simultaneously.

Step 2:

Remove the storage buffer from the magnetic beads and wash two times with wash buffer. Add now an appropriate amount of magnetic beads to the lysate. We suggest that you use sterile pipette tips for this.

Step 3:

Shaking of the MagBead/Protein mixture. We suggest automated mixing with a slower but steady speed. No vortexing! A duration of around 2 hours at 4 °C is what we see as sufficient.

Step 4:

Now, almost every protein of interest should have bound to a MagBead.

Step 5:

Apply a magnetic force to your magnetic beads to separate them and in turn the protein of interest from the rest of the lysate. For micro centrifuge tube we suggest our practical MagBead separator for this.

Step 6:

In the final step the rest of the cell lysate that did not bind to the magnetic beads will be removed using again sterile peptide tips. Keep the magnetic force active to avoid accidental removal of some magnetic beads. Now wash the bound proteins and elute them with elution buffer.

Optional:

Additional washing steps will increase the purity of your protein. Different types of MagBeads can require different kinds of washing buffers. To see how the corresponding washing buffer for your MagBeads is prepared, consult our protocols \u0026 datasheets page.

You will also find the necessary information to elute the proteins of interest from the magnetic beads later on if this is necessary for you. Feel free to contact us in case you have any further questions.

Find a comprehensive guide at:

https://cubebiotech.com/guidetomagneticbeads/magbeadsforproteinpurification

การวัดค่าเครื่องปรับอากาศ EP.4 | Balance Pressure

Magnetic Field of a Coil

Iron filings are used to visualize the magnetic fields generated by coils. Ampere’s circuital law is applied to a solenoid to determine the magnetic field intensity.

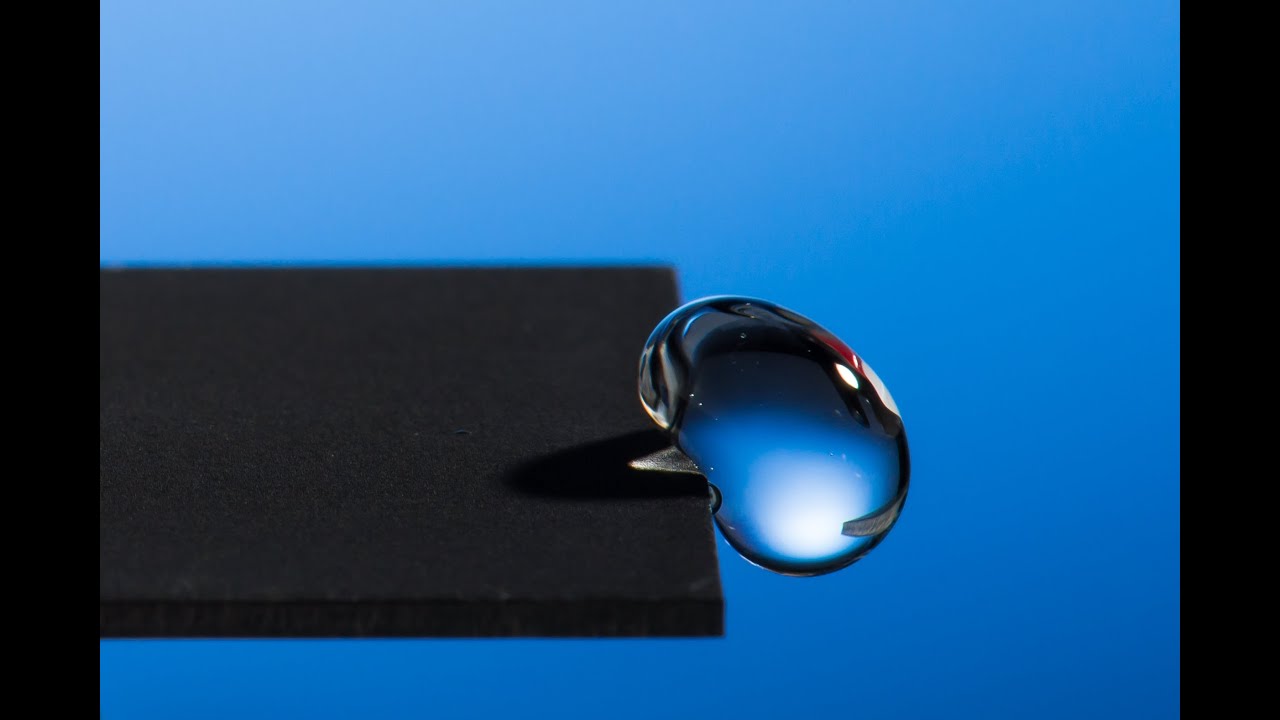

Using Lasers to Create Super-hydrophobic Materials

Scientists at the University of Rochester have used lasers to transform metals into extremely water repellent, or superhydrophobic, materials without the need for temporary coatings.

Superhydrophobic materials are desirable for a number of applications such as rust prevention, antiicing, or even in sanitation uses. However, as Rochester’s Chunlei Guo explains, most current hydrophobic materials rely on chemical coatings.

In a paper (http://scitation.aip.org/content/aip/journal/jap/117/3/10.1063/1.4905616) published today in Journal of Applied Physics, Guo and his colleague at the University’s Institute of Optics, Anatoliy Vorobyev, describe a powerful and precise laserpatterning technique that creates an intricate pattern of micro and nanoscale structures to give the metals their new properties. This work builds on earlier research by the team in which they used a similar laserpatterning technique that turned metals black (http://www.rochester.edu/news/show.php?id=2701). Guo states that using this technique they can create multifunctional surfaces that are not only superhydrophobic but also highlyabsorbent optically.

Guo adds that one of the big advantages of his team’s process is that “the structures created by our laser on the metals are intrinsically part of the material surface.” That means they won’t rub off. And it is these patterns that make the metals repel water.

“The material is so strongly waterrepellent, the water actually gets bounced off. Then it lands on the surface again, gets bounced off again, and then it will just roll off from the surface,” said Guo, professor of optics at the University of Rochester. That whole process takes less than a second.

The materials Guo has created are much more slippery than Teflon—a common hydrophobic material that often coats nonstick frying pans. Unlike Guo’s lasertreated metals, the Teflon kitchen tools are not superhydrophobic. The difference is that to make water to rolloff a Teflon coated material, you need to tilt the surface to nearly a 70degree angle before the water begins to slide off. You can make water roll off Guo’s metals by tilting them less than five degrees.

As the water bounces off the superhydrophobic surfaces, it also collects dust particles and takes them along for the ride. To test this selfcleaning property, Guo and his team took ordinary dust from a vacuum cleaner and dumped it onto the treated surface. Roughly half of the dust particles were removed with just three drops of water. It took only a dozen drops to leave the surface spotless. Better yet, it remains completely dry.

Guo is excited by potential applications of superhydrophobic materials in developing countries. It is this potential that has piqued the interest of the Bill and Melinda Gates Foundation, which has supported the work.

“In these regions, collecting rain water is vital and using superhydrophobic materials could increase the efficiency without the need to use large funnels with highpitched angles to prevent water from sticking to the surface,” says Guo. “A second application could be creating latrines that are cleaner and healthier to use.”

Latrines are a challenge to keep clean in places with little water. By incorporating superhydrophobic materials, a latrine could remain clean without the need for water flushing.

But challenges still remain to be addressed before these applications can become a reality, Guo states. It currently takes an hour to pattern a 1 inch by 1 inch metal sample, and scaling up this process would be necessary before it can be deployed in developing countries. The researchers are also looking into ways of applying the technique to other, nonmetal materials.

Guo and Vorobyev use extremely powerful, but ultrashort, laser pulses to change the surface of the metals. A femtosecond laser pulse lasts on the order of a quadrillionth of a second but reaches a peak power equivalent to that of the entire power grid of North America during its short burst.

Guo is keen to stress that this same technique can give rise to multifunctional metals. Metals are naturally excellent reflectors of light. That’s why they appear to have a shiny luster. Turning them black can therefore make them very efficient at absorbing light. The combination of lightabsorbing properties with making metals water repellent could lead to more efficient solar absorbers – solar absorbers that don’t rust and do not need much cleaning.

Guo’s team had previously blasted materials with the lasers and turned them hydrophilic, meaning they attract water. In fact, the materials were so hydrophilic that putting them in contact with a drop of water made water run “uphill” (http://www.rochester.edu/news/show.php?id=3387).

นอกจากการดูหัวข้อนี้แล้ว คุณยังสามารถเข้าถึงบทวิจารณ์ดีๆ อื่นๆ อีกมากมายได้ที่นี่: ดูบทความเพิ่มเติมในหมวดหมู่Sales experience